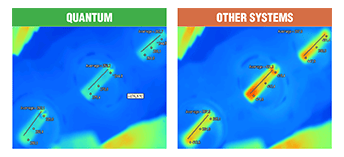

Get superior plunger cooling using lower air pressure than conventional forming systems. The Quantum Cylinder and Process equipment work together to allow the Forming Plunger to be cooled throughout the entire forming cycle.

- No thermal shock to the Plunger or overlay material

- Minimal dimensional growth of the Forming Plunger

- Closer fit to Guide Ring

- Lower pressures required due to Continuous (360°) cooling of the Plunger

- Having cooling on during Press Time reduces Plunger Up Pressing Pressure

- Lower temperatures result in higher speed potentials and reduced sticking

- The Plunger, Internal Cooler and Guide Ring will have a longer production life